| HISTORY | MAGIC TRICKS | ROAD TRIPS | FUTURE GAMES | "NEWS" OF THE WORLD | ||

|

WE DO NOT OFFER ONLINE PURCHASING.

|

|---|

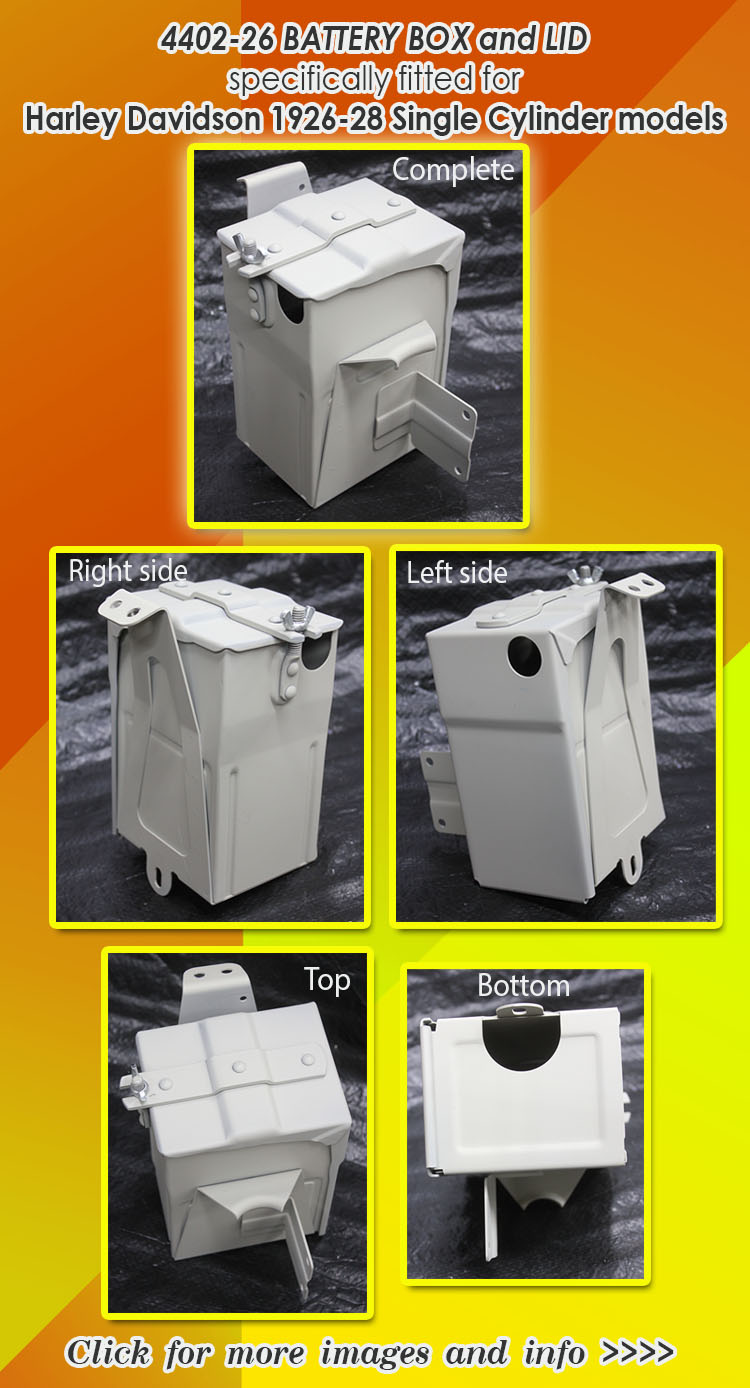

Replicant Metals NEWEST OFFERING is the meticulously designed and perfectly crafted recreation of 4402-26 BATTERY BOX and LID specifically fitted for Harley Davidson 1926-28 Single cylinder models. At the launch of the 2016 CannonBall in Atlantic City, I was discussing the future of vintage motorcycle parts with Lonnie Sr., and we agreed that the single cylinders were a much overlooked and now highly sought after 1920-30s motorcycle. Once thought of as an economy model or an entry level machine, it has been realized they were made in huge volumes, and even though most were exported to Europe, the Scandinavian countries, Australia and New Zealand, many remain in the continental USA. Large volumes of motor parts and common fixings exist that were shared with early small twins, but there is still a vast necessity for sacrificial and high exposure parts. Replicant Metals has been providing Singles Models primary covers, handlebars, chain guards, rear stands, saddles, later-singles fenders, and several small items for many years. We previously provided forty-five and Big Twin battery boxes, but had not ventured into the singles marketplace, one of the most sought after and often missing parts for single cylinder machines. After contact with our most highly regarded artisan of die formed parts, samples were located and scanned. NOW we are INTRODUCING the first batch of 4402-26 battery boxes with lids for 1926-28 models. Flawlessly executed in proper gauge steel with all the exacting details Replicant Metals is known to provide. Fits perfectly and will pass any AMCA scrutiny your machine may be subjected to, museum quality without the rust and dents. Watch RM website for more Single Cylinder parts as we help to remember the past. If your machine deserves the BEST you require Replicant Metals. My best ~ Tom |

Replicant Metals • 717-202-3300 • info@replicantmetals.com • Pennsylvania USA

Copyright 1996-2023. Replicant Metals. All rights reserved.